Rethinking Orthodontics Through Design

Project Overview

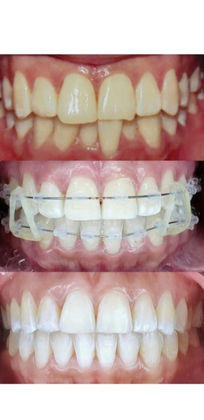

'Slide H' is an innovative orthodontic bracket system designed in collaboration with Dr. Felipe Ossa and Slide OD to improve comfort, aesthetics, and usability in dental treatments. Unlike traditional bulky brackets, Slide Od offers a discreet and minimally invasive design that enhances patient confidence while ensuring precise, clinician-friendly performance.

As the product designer, I led the design and prototyping process, focusing on user needs, mechanical functionality, and production scalability.

My Role:

Lead Industrial/Product Designer

Status:

Commercial Launch / Patent Pending

Timeline:

2022-2024

Client:

Dr. Felipe Ossa - Slide Od

The Problem

Traditional orthodontic brackets are effective but come with significant drawbacks: they're bulky, uncomfortable, and highly visible. The industry considered full clinical performance in a minimally invasive form factor nearly impossible.

The Design Process

Transforming a dental engineering challenge into a market-ready innovation required a methodical yet creative approach. My process balanced rigorous user research with bold technical experimentation, ensuring every design decision was grounded in real clinical needs while pushing the boundaries of what orthodontic technology could achieve.

Each phase built upon deep collaboration with Dr. Ossa, creating a feedback loop between clinical expertise and design innovation.

August 2022

Discovery & Requirements

Immersed myself in the clinical environment to understand the real challenges. Shadowed Dr. Ossa's practice for weeks, observing patient reactions and clinical workflows. Conducted structured interviews with 20+ patients to map emotional and physical pain points with traditional brackets.

Key Insights: Patients prioritized invisibility over everything else, while clinicians needed precise force control and efficient application workflows.

September 2022

Concept Development

Started with rough sketches exploring radically different approaches. Moved from 2D sketching to resin and 3D printed models to understand spatial relationships. The breakthrough came through force vector analysis—realizing we could redirect mechanical loads through geometric innovation rather than material strength alone. Here is when the 'Slide H' concept was born.

Innovation Moment: Traditional brackets fight against the tooth—our design works with natural tooth geometry to distribute forces more efficiently.

October 2022

Prototype & Validation

Built 15+ iterations progressing from rough 3D printed concepts to precision-machined prototypes. Each iteration tested specific hypotheses about form, function, and patient comfort. Collaborated directly with Dr. Ossa to validate clinical performance through real patient cases.

Testing Protocol: Patient comfort surveys, clinical effectiveness measurements, and long-term wear studies guided each design iteration.

December 2022

February 2023

Technical Development

Translated design intent into manufacturing reality. Defined precise tolerances for medical-grade materials, established quality control protocols, and worked with specialized orthodontic manufacturers to ensure scalable production without compromising the innovative design.

Manufacturing Challenge: Achieving 0.1mm precision tolerances at production scale while maintaining biocompatibility standards.

The Impact

+5000 patients treated

With Slide H across Latin America

60% Size Reduction

Compared to traditional bracket system

Knowledge Transfer

Dr. Ossa teaches Slide H certification courses and Training programs established across Latin America.

Clinical Success

-

Patent-pending status secured

-

Zero clinical failures in initial deployment

-

Established across Latin America

Market Transformation

-

Positioned Slide OD as industry innovation leader

-

Top competitor in "invisible orthodontics" category

-

Generated international interest for knowledge transfer

Key Design Innovations

Slide H introduces a new standard in orthodontics through compact, patient-friendly, and clinically effective design. Targeting real needs—comfort, discretion, precision, and scalable production.

Geometric Optimization

Developed a proprietary shape that distributes forces more efficiently, reducing overall device size by 60% while maintaining clinical effectiveness.

Patient-Centric Design

Incorporated rounded edges and smooth transitions to eliminate sharp contact points that cause discomfort in traditional systems.

Manufacturing Excellence

Optimized design for efficient production while maintaining precision tolerances required for medical-grade orthodontic devices.